Pipeline sand pump

Product introduction:

ZNG series pipeline wear-resistant mud pump is designed based on the principle of pipeline pump. The flow parts are made of high-strength wear-resistant alloy material, which has good wear resistance. The flow passage is large. Sand, mineral slurry, coal slurry, sand and other media of solid particles. It can replace the traditional horizontal mud pump, used in sewage treatment plant, thermal power plant slag extraction, steel plant iron slag, industrial and mining enterprises, etc.

Model meaning:

ZNG-pipeline mud pump

ZNGX-stainless pipeline mud pump

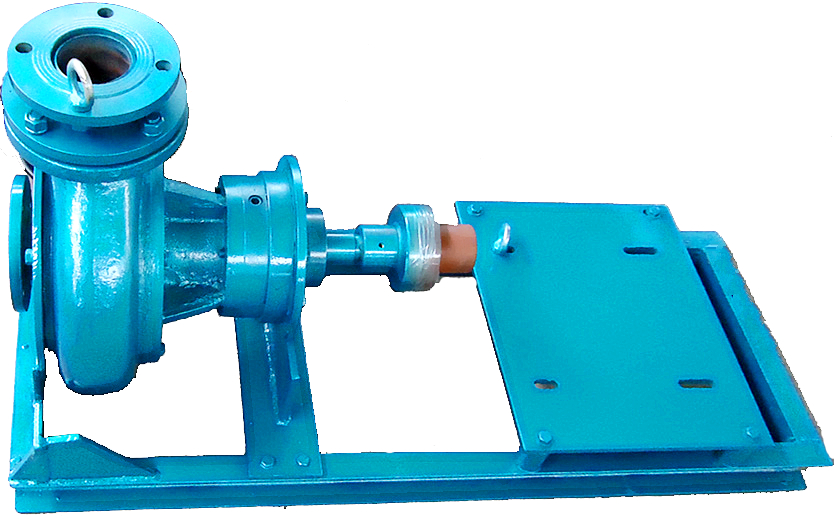

WZNG- Horizontal pipeline sediment pump

WZNGX- Stainless steel horizontal pipeline sediment pump

The pump body uses a large flow channel design, which has a large granularity and good passability.

The impeller, pump body and other flow parts are made of wear-resistant alloy material, which is wear-resistant.

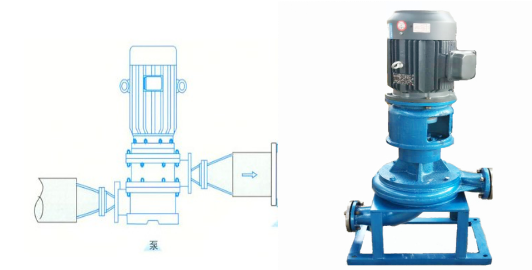

Adopt vertical structure, save space, easy installation and high efficiency of the whole machine.

The pump has an oil chamber and a hard alloy mechanical seal.

The installation method of ZNG pipeline pump motor is vertical, the flow direction is the same as the arrow direction on the pump body. This adopts the principle of low in and high out.

Product Usage:

1. Perform secondary pressurization on the pipeline of the submersible sediment pump to realize long-distance transportation of sediment.

2. Instead of traditional horizontal pumps, coal mines, power plants, sewage treatment plants and other enterprises transport slurry containing solid particles, etc., and the transport medium concentration can reach over 40%.

3. It is suitable for transporting tailings slurry, sand slurry, slag, mud, mortar, quicksand and mobile sludge from urban sewage channels, as well as fluids and corrosive liquids containing silt residue.

4. Conveying medium such as sand, ore slurry, coal slurry, sand and gravel containing large solid particles.

Note before use:

1. Before starting, carefully check whether the pipeline pump is deformed or damaged during transportation, storage and installation, and whether the fasteners are loose or falling off.

2. Leakage, phase loss, overcurrent and overload protection devices must be installed before use

3. Check whether the power supply unit is safe and reliable, and the rated voltage must match the nameplate.

4. Seal the inlet and outlet flanges and pipeline flanges of the pump with rubber gaskets and connect them firmly.

5. Switch the pump shaft after the motor is installed, there should be no jamming or a lot of friction, otherwise the motor should be reinstalled immediately. The piping weight should not be added to the pump during installation to avoid deforming the pump.

Repair and maintenance of pipeline pumps

1. Regularly check the tissue insulation resistance between the pump winding and the casing. The insulation resistance should be greater than 20MΩ. Otherwise, corresponding measures must be taken to meet the requirements before use.

2. Under normal working conditions, after the electric pump works for 3-6 months, maintenance should be carried out, replacing worn and wearing parts, checking the tightening status, replenishing or replacing bearing grease and mechanical oil in the oil chamber. Ensure that the electric pump works well.

3. The pipeline booster pump is not used for a long time. The pipeline should be unloaded and the water accumulated in the pump should be drained. The main parts should be cleaned, rust-proof and dried, placed in a dry and ventilated place, and properly stored.

ZNG、ZNGX、WZNG、WZNGX model data

|

No. |

Model |

Flow rate M3/h |

Head m |

Diameter mm |

Power kw |

Granularity mm |

|

50ZNG15-25-3 |

15 |

25 |

50 |

3 |

10 |

|

|

50ZNG30-15-3 |

30 |

15 |

50 |

15 |

||

|

50ZNG40-13-3 |

40 |

13 |

50 |

15 |

||

|

50ZNG50-10-3 |

50 |

10 |

50 |

20 |

||

|

50ZNG24-20-4 |

24 |

20 |

50 |

4 |

20 |

|

|

50ZNG40-15-4 |

40 |

15 |

50 |

20 |

||

|

80ZNG60-13-4 |

60 |

13 |

80 |

20 |

||

|

50ZNG25-30-5.5 |

25 |

30 |

50 |

5.5 |

18 |

|

|

80ZNG30-22-5.5 |

30 |

22 |

80 |

20 |

||

|

100ZNG65-15-5.5 |

65 |

15 |

100 |

25 |

||

|

100ZNG70-12-5.5 |

70 |

12 |

100 |

25 |

||

|

80ZNG30-30-7.5 |

30 |

30 |

80 |

7.5 |

25 |

|

|

80ZNG50-22-7.5 |

50 |

22 |

80 |

25 |

||

|

100ZNG80-12-7.5 |

80 |

12 |

100 |

30 |

||

|

100ZNG100-10-7.5 |

100 |

10 |

100 |

30 |

||

|

80ZNG50-26-11 |

50 |

26 |

80 |

11 |

26 |

|

|

100ZNG80-22-11 |

80 |

22 |

100 |

30 |

||

|

100ZNG130-15-11 |

130 |

15 |

100 |

35 |

||

|

100ZNG50-40-15 |

50 |

40 |

100 |

15 |

30 |

|

|

100ZNG60-35-15 |

60 |

35 |

100 |

30 |

||

|

100ZNG100-28-15 |

100 |

28 |

100 |

35 |

||

|

100ZNG130-20-15 |

130 |

20 |

100 |

37 |

||

|

150ZNG150-15-15 |

150 |

15 |

150 |

40 |

||

|

150ZNG200-10-15 |

200 |

10 |

150 |

40 |

||

|

100ZNG70-40-18.5 |

70 |

40 |

100 |

18.5 |

35 |

|

|

150ZNG180-15-18.5 |

180 |

15 |

150 |

40 |

||

|

100ZNG60-50-22 |

60 |

50 |

100 |

22 |

28 |

|

|

100ZNG100-40-22 |

100 |

40 |

100 |

30 |

||

|

150ZNG130-30-22 |

130 |

30 |

150 |

32 |

||

|

150ZNG150-22-22 |

150 |

22 |

150 |

40 |

||

|

150ZNG200-15-22 |

200 |

15 |

150 |

40 |

||

|

200ZNG240-10-22 |

240 |

10 |

200 |

42 |

||

|

100ZNG80-46-30 |

80 |

46 |

100 |

30 |

30 |

|

|

100ZNG120-38-30 |

120 |

38 |

100 |

35 |

||

|

100ZNG130-35-30 |

130 |

35 |

100 |

37 |

||

|

150ZNG240-20-30 |

240 |

20 |

150 |

40 |

||

|

200ZNG300-15-30 |

300 |

15 |

200 |

50 |

||

|

100ZNG100-50-37 |

100 |

50 |

100 |

37 |

30 |

|

|

150ZNG150-40-37 |

150 |

40 |

150 |

40 |

||

|

200ZNG300-20-37 |

300 |

20 |

200 |

50 |

||

|

200ZNG400-15-37 |

400 |

15 |

200 |

50 |

||

|

150ZNG150-45-45 |

150 |

45 |

150 |

45 |

40 |

|

|

150ZNG200-30-45 |

200 |

30 |

150 |

42 |

||

|

200ZNG350-20-45 |

350 |

20 |

200 |

50 |

||

|

200ZNG500-15-45 |

500 |

15 |

200 |

50 |

||

|

150ZNG150-50-55 |

150 |

50 |

150 |

55 |

40 |

|

|

150ZNG250-35-55 |

250 |

35 |

150 |

42 |

||

|

200ZNG300-24-55 |

300 |

24 |

200 |

50 |

||

|

250ZNG600-15-55 |

600 |

15 |

250 |

50 |

||

|

100ZNG140-60-75 |

140 |

60 |

100 |

75 |

40 |

|

|

150ZNG200-50-75 |

200 |

50 |

150 |

45 |

||

|

150ZNG240-45-75 |

240 |

45 |

150 |

45 |

||

|

200ZNG350-35-75 |

350 |

35 |

200 |

50 |

||

|

200ZNG400-25-75 |

400 |

25 |

200 |

50 |

||

|

200ZNG500-20-75 |

500 |

20 |

200 |

50 |

||

|

150ZNG250-50-90 |

250 |

50 |

150 |

90 |

44 |

|

|

200ZNG400-40-90 |

400 |

40 |

200 |

50 |

||

|

250ZNG550-25-90 |

550 |

25 |

200 |

50 |

||

|

200ZNG400-50-110 |

400 |

50 |

200 |

110 |

50 |

|

|

300ZNG660-30-110 |

660 |

30 |

200 |

50 |

||

|

300ZNG800-22-110 |

800 |

22 |

300 |

50 |

||

|

300ZNG500-45-132 |

500 |

45 |

200 |

132 |

50 |

|

|

300ZNG700-35-132 |

700 |

35 |

200 |

50 |

||

|

300ZNG1000-22-132 |

1000 |

22 |

300 |

50 |